10 Use Cases of AI in the Field of Construction

Will AI make construction industry, civil engineering, and design more efficient? How will it benefit these industries? Starting from the 1980s professors and researchers from all over the world published an enormous amount of articles about use cases of artificial intelligence in the field of construction. We analyzed those articles and compiled a list of 10 most interesting examples, where AI technology used for construction performance diagnostics, intelligent planning of construction projects or creating construction robot fleet management systems.

Analogy-Based Solution to Markup Estimation Problem

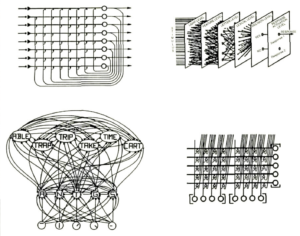

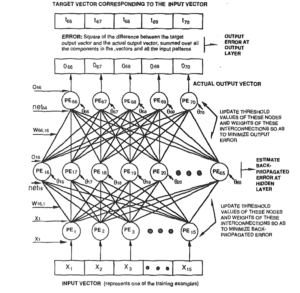

In 1994 professors Tarek Hegazy and Osama Moselhi published a technical paper, which presented a methodology for deriving analogy-based solutions to a class of unstructured problems in civil engineering. Such problems have identifiable characteristics, including: problems frequently require simultaneous assessment of a large number of quantitative as well as qualitative factors that influence the solution; traditional algorithmic and reasoning-intensive techniques are not adequate to model the problem; solutions are devised in practice primarily based on analogy with previous cases coupled with a mixture of intuition and experience; and domain knowledge is mostly implicit and very difficult to be extracted and described.

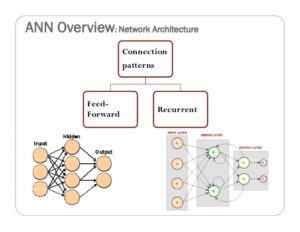

For this class of problems, artificial neural networks are most suited for developing decision aids with analogy-based problem-solving capabilities. A methodology is presented and used to develop a practical model for markup estimation using knowledge acquired from contractors in Canada and the U.S. The model design, training, and testing are described along with the generalization improvements made using the genetic algorithms technique.

Neuromodex – Neural Network System for Modular Construction Decision Making

The model helps make a decision whether to use a conventional “stick-built” method or to use some degree of modularization when building an industrial process plant. This decision is based on several decision attributes which are divided into following five categories: plant location, environmental and organizational, labor-related, plant characteristics, and project risks.

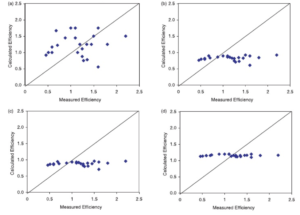

The neural network is trained using cases collected from several engineering and construction firms and owner firms of industrial process plants. In this paper, an overview of modular construction is provided and the reasons for using a neural network are also discussed. The architecture, representation, and training procedure for the selected neural network paradigms are described. The performance of the trained neural network system is compared with the recommendations provided by human experts. The results of statistical tests performed to validate the system are also resented.

Neuroform – Neural Network System for Vertical Formwork Selection

Neuroform is a computer system that provides the selection of vertical formwork systems for a given building site. The reasons for choosing a neural network approach instead of a traditional expert system are discussed. The selection of an appropriate neural network model, its architecture, representation of the network training examples, and the network training procedure are described. The details of the user interaction with the trained neural network system are presented. The performance of Neuroform is validated comparing its recommendations with that of Wallform, a rule-based expert system for vertical formwork selection. A statistical hypothesis test, conducted on the recommendations of Neuroform when partial inputs are given, demonstrates the system’s fault-tolerant and generalization properties.

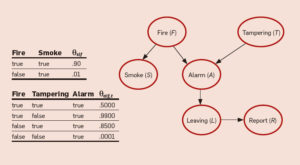

Belief Networks for Construction Performance Diagnostics

Belief networks, also referred to as Bayesian networks, are a form of artificial intelligence that incorporates uncertainty through probability theory and conditional dependence. Variables are graphically represented by nodes, whereas conditional dependence relationships between the variables are represented by arrows. A belief network is developed by first defining the variables in the domain and the relationships between those variables. The conditional probabilities of the states of the variables are then determined for each combination of parent states. During evaluation of the network, evidence may be entered at any node without concern about whether the variable is an input or output variable.

An automated approach for the improvement of the construction operations involving the integration of the belief networks and computer simulation is described. In this application, the belief networks provide diagnostic functionality to the performance analysis of the construction operations. Computer simulation is used to model the construction operations and to validate the changes to the operation recommended by the belief network.

Building KBES for Diagnosing PC Pile with Artificial Neural Network

Diagnosis of damage of prestressed concrete piles during driving is an important problem in foundation engineering. An effort to build an expert system for the problem is described in this paper. To overcome the bottleneck of knowledge acquisition, an artificial neural network is used as the learning mechanism to transfer engineering experience into usable knowledge. The back- propagation learning algorithm is employed to train the network for extracting knowledge from training examples.

The influences of various control parameters (including learning rate and momentum factor) and various network architecture factors (including the number of hidden units and the number of hidden layers) are examined. The results prove that the artificial neural network can work sufficiently as a knowledge-acquisition tool for the diagnosis problem. To apply the knowledge in the trained network, a reasoning strategy that hybridizes forward-and backward-reasoning schemes is proposed to realize the inference mechanism.

Modeling Initial Design Process using Artificial Neural Networks

The preliminary design model is of vital importance in the synthesis of a finally acceptable solution is a design problem. The initial design process is extremely difficult to computerize because it requires human intuition. It has often been impossible to form declarative rules to express human intuition and past experience. The suitability of an artificial neural network for modeling an initial design process has been investigated in this paper.

Development of a network for the initial design of reinforced-concrete rectangular single-span beams has been reported. The network predicts a good initial design (i.e., tensile reinforcement required, depth of beam, width, cost per meter, and the moment capacity) for a given set of input parameters (i.e., span, dead load, live load, concrete grade, and steel type). Various stages of development and performance evaluation with respect to a rate of learning, fault tolerance, and generalization have been presented.

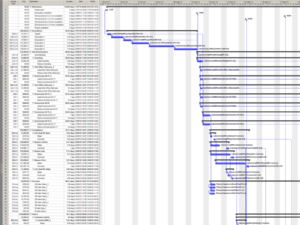

Intelligent Planning of Construction Projects

Knowledge representation and reasoning techniques derived from artificial intelligence research permit computers to generate plans, not merely analyze plans produced by humans. They explicitly represent knowledge about how to generate plans in the form of initial and goal states, descriptions of actions along with their preconditions and effects, and a control structure for selection new actions to insert into a project plan.

Researchers Kartam and Levitt, have chosen the system for interactive planning and execution (SIPE) to investigate the utility of AI planners for construction project planning.

They were modeling a multistory office building project for construction planning, implementing SIPE to plan this project, and describing SIPE’s performance in planning the construction of large-scale multistory buildings. With the use of a frame hierarchy, generic operators, and a constraint-based approach, SIPE can generate logically correct activity networks for multistory building construction from a description of the components of a facility. To model such construction projects in a concise and uniform framework, they showed the usefulness of some underlying principles for establishing ordering relationships among the project components involved in construction activities.

Construction Robot Fleet Management System

The application of robotic equipment to the execution of construction tasks is gaining attention by researchers and practitioners around the world. A number of working prototype systems have been developed by construction companies or system manufacturers, and implemented on construction job sites. Several Japanese construction firms have already developed their own fleet of construction robots. In 1991 Skibniewski and Russell described a HyperCard prototype of the construction robotic equipment management system (CREMS), developed as a response to the need to effectively manage diverse robots on future construction sites.

The utility of this system lies in optimizing the robot performance of work tasks on as many construction projects in a contractor’s portfolio as feasible. Thus, economic benefits of robot use can be achieved more easily. Thus, robot development costs can be recovered faster, and robot use can be distributed over more applications and types of construction tasks.

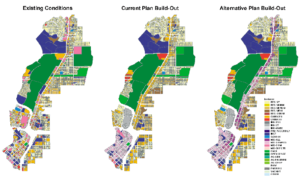

Bridge Planning Using GIS and Expert System Approach

In the planning process of a new road network, the planner should consider possible locations of bridges and tunnels. The selection of the best alignment imposes the need to investigate the effect of the location of each bridge on the bridge type that fits this location. This task has not been done so far because of the large volume of data needed and the complicated interaction between many factors. Considering this task in the early stage of road alignment planning can result in a more rational design.

Geographic information systems and expert systems are proposed as two methodologies that can help in comparing candidate sites and candidate types simultaneously. Having this computation power, quantitative comparison can be done faster and much more precisely than in the case of conventional simplified methods. This can result in improving the design of the road network in general and in having bridges designed to meet the requirements of erection, maintenance, driving comfort, and landscape.

DAPS: Expert System for Structural Damage Assessment

Assessment of structural damage is a complex subject imbued with uncertainty and vagueness. This complexity arises from the use of subjective opinion and imprecise numerical data. An analysis of the structural integrity of a buried concrete box structure is accomplished using combined nonnumeric and numeric information. Expert opinions on structural damage are used to develop the nonnumeric portion of the code. Fuzzy sets are used to quantify linguistic variables since this type of information is inherently vague and imprecise.

Because of the size and the complexity of the problem, a numerical method in the form of a fuzzy weighted-average algorithm is used instead of rules to synthesize the nonnumeric information. The damage assessment paradigm is subdivided into smaller problems, which in turn are represented in antecedent-consequent pairs as rules. These rules and numerical data form the knowledge base. The processing of this information is controlled through an expert system shell, which retrieves necessary facts from the user and the knowledge base using an appropriate search strategy. Numeric data are manipulated in the expert system through calls to external subroutines and data bases. This information is then interpreted through the use of production rules.

Construction is a very accurate industry, where size and complexity of the problems requires a number of specific methods and algorithms. That’s where AI stands. Whether artificial intelligence helps in bridge planning using GIS, modeling initial design process using artificial neural networks or effectively managing diverse robots on construction sites.

Author: AI.Business